TODAY's KEY

TO TOMORROW's SOFTWARE

Integration

Integration is Ulysses Systems’ commitment to the maritime enterprise.

Ulysses Systems Task Assistant® integrations satisfy the maritime enterprise’s need for innovation.

They also secure the continuity of enterprise software by bridging the gaps between precious legacy data, existing software and new systems.

Early on, it became clear to us that the more sophisticated shipping enterprises software needs are, the greater the need for a vendor with integration expertise. This foresight is the foundation of Ulysses Systems integration culture. And it has spurred the company into realizing exceptional integration features, winning us recognition across continents for continuous technological advances.

Integration, essentially, warrants out-and-out focus on usability and good workmanship. And this is where the refinement comes in. Because, as in translation between two languages, we don’t simply translate words. We convey, instead, the context of a narrative within which the words exist. Likewise with Integration. Integration between collaborating applications must provide for the story behind every process, the context of the story and the purpose before matching attributes and accommodating data exchanges.

Refinement in Integration

Refinement in integration is not just nice to have, it’s a necessity. Because integration is not a “series of points” solution for data exchange. As we mention in our introduction: Integration, actually, is making sure that the story behind every process can be accommodated by all collaborating applications without loss of resolution.

We don’t just join systems

We don’t just join systems. We map and persist processes and ensure these are in concert, when this requires two or more systems to merge. And the logic is clearly visible, therefore traceable. So, it also improves, and the improvements execute in real time. So, our customers can adjust integrations with existing and new applications and implement and run them immediately!

Consequently, the modular structure of the Ulysses Systems Integration Engine is fully capable of building the enterprise IT ecosystem that satisfies your organizational IT needs. Without, however, putting the continuity of enterprise software at risk.

Continuity of Enterprise Software

Taking integration seriously means supporting the maritime enterprise’s need for continuity of enterprise software. Continuity of enterprise software includes bridging the gaps between precious legacy data and new systems, and also integrating semi-structured content (for example, company emails) with your digitized processes.

Legacy data

Legacy data constitutes the historical foundation of an organisation’s information ecosystem, offering insights into past operations, trends, and patterns. It provides context for current data analysis and can be important in shaping organisational decision-making, strategic planning, and future growth. As such it is a valuable resource.

Maritime enterprises, therefore, would like to persist their legacy data while pursuing current data from new systems. And as in every industry, this means that company departments managers, who inherit products with their legacy data, have an integration problem: Who will integrate the legacy systems with the highest productivity tools?

Bridging the gaps

Familiarity with the software challenges of the maritime enterprise makes Ulysses systems an ideal partner in bridging the gaps between precious legacy data, existing systems and new systems.

And Ulysses Systems integration expertise makes us your ideal partner in building your enterprise IT Ecosystem. Thanks to a unique enterprise model, development speed and transparency are characteritic of Ulysses Systems integrations. As a result customers can expect quick development of extensions to existing software and new solutions, for example:

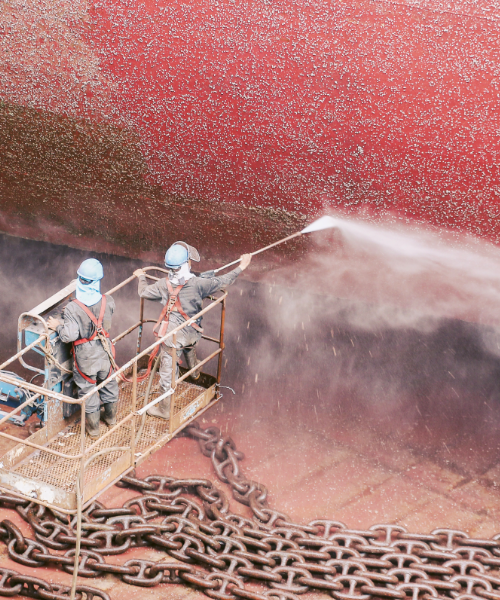

- Maintenance, Drydock and Automated Crew Experience that reduces maintenance and drydock costs with efficient crew skills match

- E-procurement and Warehousing

- Performance monitoring Integrations

- IoT devices Integrations

- Vetting and Class Society Portals Integrations

Also, OS Integrations Ulysses Systems TA Platform Applications integrate smoothly with 3rd party solutions such as D365, Oracle Financials and SAP.

Ulysses Systems and VesselMan Integrations

“Supported by a grant from Iceland, Liechtenstein and Norway through the EEA Grants Greece 2014-2021, in the frame of the Business Innovation Greece Programme”

The first collaboration between the two companies resulted in the Connected Maintenance and Drydock System (CMDS). CMDS brings together Ulysses Systems Task Assistant®, an asset management software application for planned maintenance of sea-going vessels, and VesselMan’s proprietary software for dry-docking operations.

Click on the button to read about the product.

The second collaboration between the two partners is a Crew Experience Application, which builds upon CMDS while also constituting a standalone solution. It tackles the business- sensitive concern of crew experience recording and sharing. As a result, the marine enterprise will experience added cost-efficiency derived from optimised manning, ship maintenance and operational performance. Click on the button to read about the product.